If you’ve ever worked in industrial automation, energy monitoring, or building management systems, chances are you’ve heard of the MODBUS Protocol. Developed in 1979 by Modicon (now Schneider Electric), the MODBUS protocol is one of the most widely used communication protocols for connecting electronic devices and field instruments with controllers, PLCs, HMIs, and SCADA systems.

In simple terms, MODBUS acts as a common language that allows devices from different manufacturers to communicate seamlessly. Whether you’re an engineer, technician, or automation enthusiast, understanding how the MODBUS protocol works is crucial for troubleshooting and system integration.

In this beginner-friendly guide, you’ll learn:

- What the MODBUS protocol is

- Its communication types

- How it works

- Real-world applications

- And tips for proper setup

Let’s dive into the world of MODBUS!

Table of Contents

What is MODBUS Protocol?

MODBUS Protocol is a serial communication protocol used for transmitting information over serial lines between electronic devices. It allows communication between a master device (like a PLC or SCADA system) and slave devices (like energy meters, sensors, RTUs, etc.).

Key Characteristics:

- Open and royalty-free

- Lightweight and simple

- Supports multiple device connections

- Easy to implement and debug

- Works with serial and TCP/IP networks

Why is MODBUS So Popular in Industry?

- Compatibility: Works across many brands and devices

- Simplicity: Minimal overhead, readable message structure

- Reliability: Proven and robust in industrial environments

- Scalability: Connects multiple devices over one network

Types of MODBUS Protocols

There are several variants of the MODBUS protocol. Each has a different physical layer or transport method.

1. MODBUS RTU (Remote Terminal Unit)

- Uses RS-232 or RS-485 serial communication

- Binary data format

- Compact and faster

- Widely used in industrial environments

2. MODBUS ASCII

- Data is transmitted in readable ASCII characters

- Slower than RTU due to larger message size

- Used where communication media is noisy or error-prone

3. MODBUS TCP/IP

- Communicates over Ethernet using IP protocol

- Supports faster transmission

- Easily integrated into modern IT networks

How Does MODBUS Protocol Work?

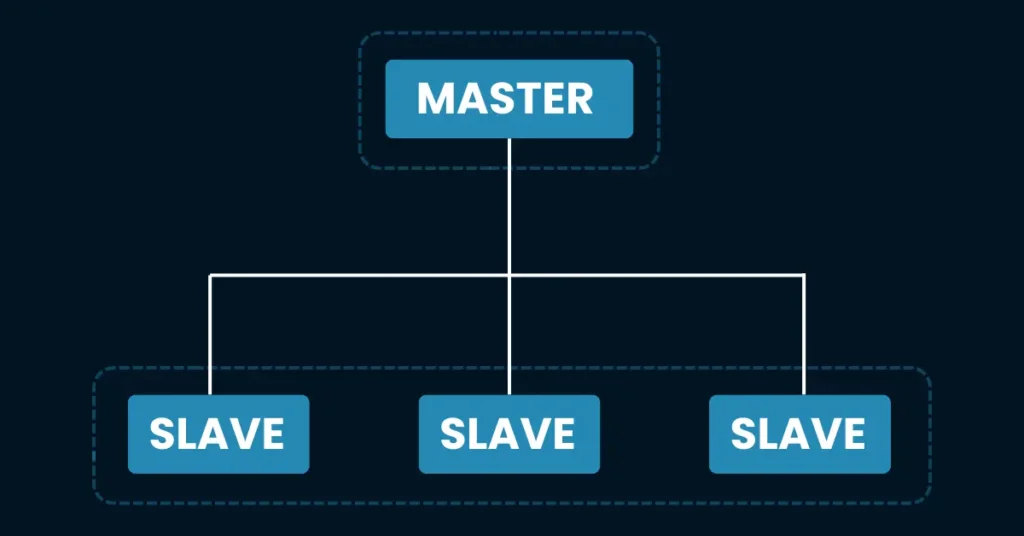

MODBUS follows a Master-Slave architecture. Here’s how it works:

Communication Flow:

- Master sends a request to a specific slave device.

- The slave processes the request.

- The slave responds with the requested data or confirmation.

Basic Message Structure:

Each MODBUS message includes:

- Slave ID (Address) – Identifies the slave device (1-247)

- Function Code – Tells the slave what to do (read, write, etc.)

- Data – The information needed for the task (e.g., register address, number of registers)

- CRC/Error Check – Ensures message integrity

Real-World Example: MODBUS in Action

Scenario: Monitoring Energy with MFM Meter

Let’s say you have a Multifunction Meter (MFM) connected to a PLC using MODBUS RTU. You want to monitor real-time voltage, current, and energy usage.

- The MFM is assigned MODBUS Slave ID 3

- You use Function Code 03 (Read Holding Registers)

- The voltage register is at address 40001 (hex address: 0x0000)

- You request 2 registers (since voltage is a 32-bit value)

Step-by-Step: Setting Up MODBUS Communication

To ensure smooth MODBUS setup, follow these steps:

1. Check Device Support

- Ensure both master and slave devices support the same MODBUS type (RTU/ASCII/TCP).

2. Match Communication Parameters

- Baud rate (e.g., 9600)

- Parity (None/Even/Odd)

- Stop bits (1 or 2)

- Data bits (typically 8)

All devices on the same MODBUS RTU network must match these settings.

3. Assign Unique Slave IDs

- Every slave must have a unique address (1-247).

- Master typically uses address 0 or is unaddressed.

4. Use Correct Wiring

- For RS-485: Use twisted pair cable (A/B lines)

- Maintain grounding and shielding to reduce noise

- Keep cable length under ~1200 meters

5. Use a MODBUS Master Tool (for testing)

Tools like:

- ModScan

- Simply Modbus

- QModMaster

help test the connection before PLC/SCADA integration.

6. Read Device Register Map

- Manufacturers provide register mapping in the manual

- Know which address holds the data you need

Best Practices and Tips for Accurate Setup

Here are tips to avoid common pitfalls in MODBUS setups:

✅ Always use termination resistors (120 ohms) at the end of RS-485 lines

✅ Avoid using star topology with RS-485 — use daisy-chaining

✅ Keep ground reference common across devices

✅ Log and analyze using software during commissioning

✅ For long runs, consider using MODBUS TCP/IP with repeaters or converters

Conclusion

The MODBUS Protocol remains a powerful and essential tool in industrial and building automation. Its simplicity, reliability, and widespread adoption make it a go-to solution for device communication.

By understanding how MODBUS works, the different types (RTU, ASCII, TCP), and following best practices for setup, even beginners can confidently integrate and troubleshoot MODBUS systems.

Whether you’re reading energy data from a meter, controlling a VFD, or connecting a remote I/O device — MODBUS makes it possible.

Frequently Asked Questions (FAQs)

What’s the difference between MODBUS RTU and MODBUS TCP?

- RTU uses serial communication (RS-485), while TCP uses Ethernet.

Can I use MODBUS with SCADA systems?

- Absolutely! MODBUS is one of the most common protocols in SCADA.

- How many devices can be connected in MODBUS RTU?

- Up to 247 slave devices with unique addresses.